Workplace Safety: 5 Essential Dust Collection System Precautions

Dust exposure in manufacturing is more than just a compliance issue—it’s a matter of protecting your workforce and ensuring long-term operational success.

A well-maintained dust collection system doesn’t just meet safety standards—it enhances productivity, reduces downtime, and boosts employee morale. By proactively managing dust, you’re not only safeguarding your employees but also optimizing your operations for better efficiency and cost savings.

Let’s look at five essential precautions that can make your workplace safer and your dust collection system more efficient.

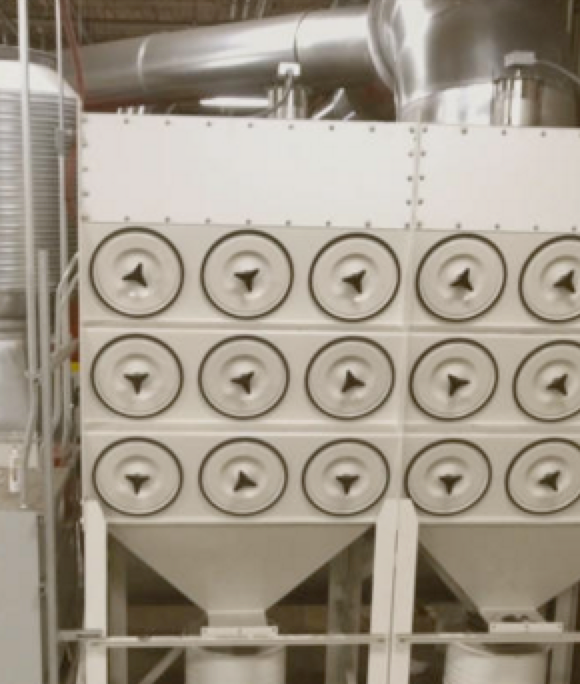

1. Stay Ahead with Timely Filter Changes

Dust collector filter changes will vary based on the application. It's important to change your dust collector filters as often as recommended by the manufacturer. Certain dust collector cartridge filters can operate for up to two years or longer. Applications with heavy dust loads will require more frequent filter changes.

Our dust collector replacement filters are built to withstand high volume dust loads - providing a longer filter life and air that is cleaner than industry standards.

Benefit: Changing filters on schedule reduces the risk of clogged filters, improving system efficiency and air quality. This proactive step minimizes unplanned downtime and costly repairs, helping to maintain optimal production levels and reducing overall maintenance costs.

2. Maximize Efficiency with Pulse/Clean on Demand

Dust build-up causes a pressure drop across the cartridge filters. The drop in pressure is constantly being monitored by a photohelic switch/gage and when it exceeds a preset limit, the gage activates a cleaning cycle - the valves pulse. A higher impact pulse results in less frequent intervals.

Benefit: Utilizing pulse/clean on demand keeps filters cleaner for longer, reducing the frequency of filter replacements and ensuring continuous system performance. This leads to less downtime, lower maintenance expenses, and prolonged filter lifespan, while maintaining air quality and compliance.

3. Protect Your Facility with Explosion Protection

Various NFPA standards require that dust collection systems have a way to prevent the transmission of energy from a fire or explosion to a building or work facility. Through extensive testing, BOSS developed High-Speed Abort Gates and/or No Return Valves to be installed upstream of the dust collector.

• High-Speed Abort Gates prevent hazardous air from returning into work environments by automatically venting harmful gases to the atmosphere, should a fire and/or explosion occur.

• Explosion Isolation Devices are required on all suction side ducts that transport material with a Kst value above zero. Installing No Return Valves protects employees and facilities from the damaging impact of a baghouse or filter explosion.

Benefit: Installing explosion protection measures like high-speed abort gates and isolation valves not only safeguards your workers but also prevents costly damage to equipment and structures. This minimizes the risk of production stoppages, avoids fines due to safety violations, and ensures long-term operational continuity.

4. Ensure Safety by Keeping Hoppers Dust-Free

Hoppers are designed to funnel dust into a storage bin, not to store dust.

When dust accumulates in a hopper there is a potential risk of fire or deflagration. Storing dust in hoppers can clog dust collection systems and stop the pulse/clean on-demand feature from working.

Benefit: Dust accumulation in hoppers can lead to hazardous conditions, including fires or explosions. Keeping hoppers dust-free reduces these risks, preventing downtime and costly damage to both your dust collection system and facility. It also ensures compliance with safety regulations, safeguarding your workforce.

5. Safeguard Your Ducting Systems for Long-Term Reliability

Dust collection ductwork draws particulate away from industrial processing machines to filter and clean air that is either returned to the work environment or exhausted outside of the facility.

The NFPA, National Fire Protection Association, requires that dust collector ductwork is protected. Dampers and Isolation Valves safeguard ducting systems from the risk of fire or deflagration.

Benefit: Properly maintaining your ductwork prevents leaks and blockages that can reduce system efficiency. This ensures that your dust collection system works at peak performance, avoiding costly repairs and minimizing the risk of hazardous dust buildup. Keeping ducting systems in optimal condition leads to increased system longevity and energy savings.

With these tips, you can significantly reduce risks. It is also essential to stay updated on the latest safety standards and best practices in your industry. Get in touch with our specialists if you have any questions about replacement dust collector filters and safety measures.

You may also like:

• Signs Its Time to Replace Your Dust Collector Cartridge Filters

• Are You Using the Right Dust Collector Filters?

• How Ducting Can Impact Dust Collector Filter Performance

© 2026 Air Cleaning Specialists, Inc (An Authorized Clark Filter Distributor). Return Policy

Need Dust Collection Ducting? We Recommend Nordfab Ducting

Covid-19 Plan

We Are Open, Essential, and Shipping On Time!

As a manufacturer and distributor of Air Cleaning, Ducting, and Filtration products we are proud to have been identified as an essential business. We will remain open for business performing essential operations during this crisis, supplying industrial, military, and healthcare operations with our products. We are shipping orders on time, with no delay in manufacturing.

Our phone lines are open from 9am-5pm central time, Monday through Friday. Our staff is working remotely wherever possible and we will maintain a bare minimum staff on site to perform basic operations of order processing and accounting. Our onsite staff will follow the appropriate best practices and guidelines set forth by OSHA's latest release of "Guidance on Preparing Workplaces for COVID-19."

These are unprecedented times and we are committed to protecting both our employees and our communities. Clean air has never been more important, and we're making sure our customers have everything they need. From those working from home who need high quality air filters, to the other essential businesses we supply products to, we're here for you.

We thank you for your support and your business and we hope that this will all be over soon.